Chinese Porcelain

An Introduction to Chinese Porcelain

- Why porcelain called china?

-

What is Porcelain?

- Difference between Stoneware, Earthenware, and Porcelain

-

How is Chinese Porcelain Made?

- Four ways 1.2.3.4.

-

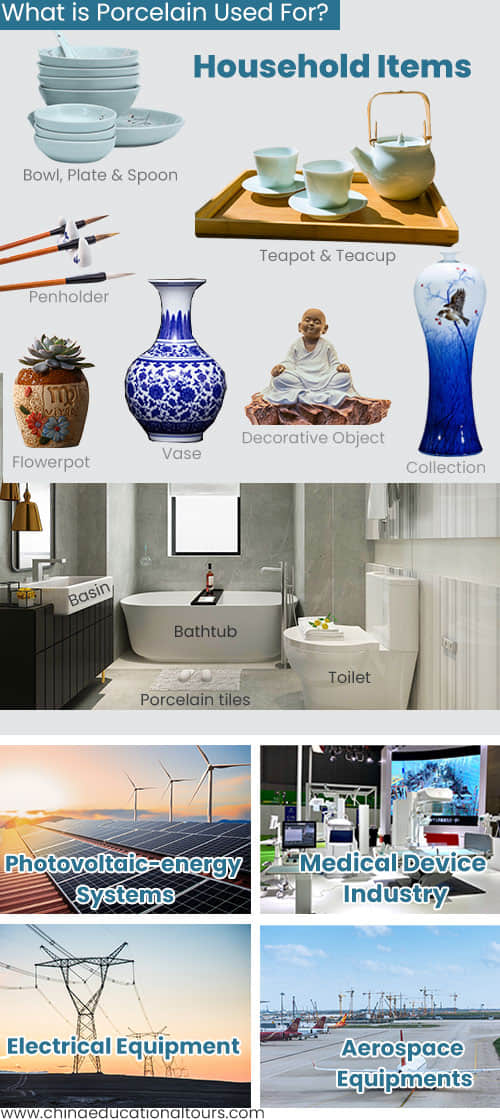

What is Porcelain Used For?

- Household items, Vase, Porcelain tiles, Medical device industry, Electrical equipment...

Why porcelain called china?

As you stack the dishes into the dishwasher, or carefully arrange some flowers into your best vase, do you ever wonder exactly why many people refer to these articles as "china", and whether it has anything to do with the country of that name? The simple answer is 'yes', the material is named after its country of origin.

Of course the name "china" does not necessarily refer to all pottery and ceramics, and not all ceramics originated in China. However porcelain definitely has its roots in ancient Chinese expertise.

Many people are so inspired by the exquisite beauty of pieces of fine china, especially porcelain, that they are willing to not only pay a higher price for the utilitarian kitchen and bathroom commodities, but also to invest large sums of money in porcelain collectibles, both ancient and modern.

So What is Porcelain?

Despite being in common use, there is nothing mundane about porcelain pieces. They are so much more than just pottery or ceramics.

The words pottery, ceramics, earthenware, stoneware, china and porcelain, which are commonly used to describe clay objects, can be confusing. Ceramics articles are made of clay, and when heated to very high temperatures the composition of the clay is permanently changed. This could be pottery objects such as plate, bowls and jugs, or other ceramic items, such as knives, tiles, pipes or machine parts. The distinct characteristics of the particular ceramic is defined by the added ingredients and varied firing temperatures.

Stoneware

Stoneware is made from unrefined clay and has a gritty texture because of its sand content. Fired at 2185°F (1196°C), it is very durable, safe for oven and microwave heating, and cheaper than porcelain.

Earthenware

Earthenware is fired at a cooler 1915°F (1046°C), is porous and not as strong, unless it is glazed (and fired again) which hardens and strengthens the surface, making it then suitable for cooking. Terracotta products are a porous type of earthenware, commonly used in the garden for plant pots.

Porcelain

Porcelain is made from fine, white clay, known as kaolin, with added ingredients such as feldspar, and fired at a very hot 2300°F (1260°C). The pieces are smooth and a translucent white, very strong and especially useful in the kitchen because of being non-porous, non-stick, and dishwasher safe. Porcelain is, not surprisingly, one of the most expensive kinds of pottery.

There is a clear difference in the texture of the different types, as stoneware has a gritty texture, earthenware has a chalky feel on the bottom and will often have a shiny glaze, while porcelain is smooth and white, generally thinner and appears translucent towards the edges.

Quite apart from the durability of utilitarian porcelain pieces, the material has lent itself well to a host of artistic possibilities, and so the whole industry of porcelain collectibles has developed across the world with pieces both ancient and modern being traded for prices up to a record $84 million. Collectors look for the texture of the basic body, color of the glaze, decorative pattern, shape, and style of the pieces, as well as taking a special interest in the background stories of historical pieces. Specific colors, patterns, and decorations are well known and sought after such as several blue and white possibilities, tri-color pieces, green celadon pieces, and the popular famille-rose porcelain from the Tang era. Every home contains some porcelain, in the bathroom at least. Many restaurants and kitchens rely on porcelain to prepare and present food. But the very best and most exciting porcelain can be found in museums and galleries, and collectors' display cases. Like all good art, it is loaded with both exquisite design and fascinating stories.

How is Chinese Porcelain Made?

A skilled artist can make really detailed and beautiful pieces with porcelain. However, if the materials are not selected and mixed properly, and if the firing of the work is not precisely correct, all that hard work goes down the drain.

The craft of making porcelain originated in China where the early makers used a special kind of clay called kaolin and a type of granite called pegmatite. Nowadays, it is made all over the world, and it is mainly made of clay, specifically kaolinite, along with feldspar and silica, since the particles in all of these are extremely small. By varying the proportions of these ingredients, the properties of the porcelain can be changed.

After being carefully selected, the raw materials need to be crushed really well to make sure that all of the particles are super fine. The crushing is brought about using three kinds of equipment. Firstly swinging metal jaws crush the material. Then hammer mills, which are like hammers that move really fast, grind it further. Finally a ball mill, consisting of large rotating cylinders filled with steel or ceramic balls, further reduces the size of the particles.

The ingredients are then passed through a series of screens to ensure that all of the particles are precisely of the required size. Subsequently, water is added to make a slurry, which is filtered with a magnet to remove any iron that may be present in the mixture. Iron is commonly present and is undesirable since, if it oxidizes (rusts), it will turn the mix a yucky red color.

Now the material is ready to be shaped into a beautiful porcelain body in one of the following four ways.

Soft plastic forming

The first method is soft plastic forming, in which the porcelain material is made manually . The clay is placed in a rotating wheel and is shaped it by hands. The second method is to shape clay mechanically by jiggering. The clay is placed horizontally on a plaster mold to make it in the desired shape, and then the other side of the piece is shaped by heating. The third method is ram pressing, in which the clay is placed between two plaster molds to shape it while forcing the water out of it. With the vacuum applied on the upper half and the pressure applied on the lower half, the body is then removed from the mold.

Stiff plastic forming

The second method, used to shape less plastic bodies, is known as stiff plastic forming. Here the material is forced through a steel die, which results in a long, even sausage shape, which can then be cut into the desired length, or used as a blank for other forming actions.

Ram pressing

Thirdly, dry bodies can be shaped simply by pressing into either a rigid die, or a flexible mold. Sometimes the pressure is from one direction only, and in other cases it is pressed equally from all sides.

Pouring the wet slurry directly into a mold

The fourth method involves pouring the wet slurry directly into a mold which is porous. The liquid drains out through the mold, leaving a rigid layer of porcelain which can be removed.

Once the porcelain has been shaped, it goes through its first firing, or bisque-firing. The temperature is relatively low, and it allows for contaminants to be vaporized, and minimizes later shrinkage.

The beauty of most clay products, including porcelain, lies not so much in its form as in the outer glaze. The glaze materials need to be ground and mixed with water, forming a slurry. The slurry also needs to be passed through a screen and a magnetic filter to remove contaminants. There are many ways to apply the glaze to the bisque-fired porcelain. It can be delicately painted on with a brush, or poured or sprayed over the piece, or the piece can be dipped into it. Varying the proportions of the individual ingredients in the glaze will produce different effects.

Probably the most well-known porcelain pieces are characteristically blue and white. To create this stunning style, firstly pieces are created as clean, shaped white clay, and bisque fired. The intricate blue designs are then painted on, usually with cobalt oxide. Then the piece is coated with a layer of transparent glaze before the final kiln firing.

Finally the porcelain ware must be fired in a kiln. Some kilns have a single sealed chamber and can fire only one batch of ware at a time. However the large commercial kilns are constructed inside a tunnel several hundred feet long. This way the ware can be moved from one zone to another, with each one continuously set to a particular temperature such as a preheating zone, a central firing zone, and a cooling zone.

The scientific basis for the firing process is complex, as firstly the carbon-based impurities are burnt out, particular chemicals decompose, and gases are produced which must be released from the ware. But eventually the feldspar and flint react with those decomposing minerals to form liquid glasses which shrink and bond the grains. Finally, as the ware cools, the liquid glasses solidify.

The porcelain product emerges from the kiln strong, white and translucent and ready to be used in so many ways. The artistic pieces emerge in all their delicacy and beauty, with the colors embedded in the strong, shiny glaze.

What is Porcelain Used For?

Maybe you have no desire to collect porcelain pieces, and you can't see the point in using "fancy" dishes at the dinner table, so you may think that porcelain use is not for you. But you might be surprised to realize how much porcelain actually affects your everyday life without giving it much thought. It seems like an old-fashioned material, and yet it has proved vital in so many ways in this technological era.

In ancient times porcelain was used firstly for household items, for preparing and serving of food. Porcelain utensils and dishes were observed to be impervious to liquid, durable even when heated, and also easy to clean and reuse. Soon porcelain items were being made for other minor household uses such as penholders and paperweights.

Decorative objects were created from porcelain, which could be used around the home as well as presented as gifts. Statues and ornate trinkets were created for wealthy people. Intricate porcelain articles featured as gifts in diplomatic exchanges. And as the rest of the world also discovered this remarkable material, porcelain was eagerly imported by the rest of the world.

Nowadays you can expect to see porcelain crockery as dinnerware, if not in your home then certainly in classy restaurants. There are also other places in your home where you definitely use porcelain. Firstly, there is the "water closet". Porcelain, sometimes referred to here as "vitreous china", is still the material of choice for the toilet stand because it is waterproof, clean, sanitary, as well as strong, rigid and very durable. It is easy to keep clean, and keeps an even temperature better than materials like stainless steel. And it is also the most popular material for your bathroom basin.

Porcelain tiles are popular for both floors and walls, especially in the bathroom, kitchen and laundry. Although porcelain is generally more expensive than other ceramic tiles, it has a lower water absorption rate, and is denser, and therefore harder, than other ceramics. In China, most floors and even external walls are tiled. Porcelain tiles can also be found on work surfaces, ledges, shelves, sills, and in some cases as roof tiles.

Another attribute of porcelain is that it does not conduct electricity, and as such it is be used in the creation of insulators for electronic applications.

It is possible that you have some porcelain inside your mouth, as dentists often use porcelain for caps and crowns. These life-like tooth restorations made of entirely porcelain, are sometimes known as porcelain jackets. Even more durable are the porcelain-fused-to-metal crowns.

Despite its performance as a utilitarian product, it is the grace and elegance of the porcelain products that make them useful in a purely artistic way. People realized very early on, that porcelain pieces are so elegant in design and exquisitely beautiful, and yet durable, that they make great collectors' items. All over the world porcelain pieces, both ancient and modern, are collected and treasured as well as exchanged for large sums of money.

Some of the interesting culturally-inspired uses of porcelain objects from earlier times make them even more desirable as collectibles. For instance there are porcelain sacrificial vessels such as incense burners which were used in special worship ceremonies, and burial items such as tomb figures.

Naturally for those who are into collectibles in a big way, it is at least partly the unshakable investment value that makes porcelain most useful. But for many it is simply an attraction to the delicate artwork.

Chinese Woodcarving Art

Chinese Woodcarving Art  How Chinese Palmistry Works

How Chinese Palmistry Works  Chinese Lacquerware

Chinese Lacquerware  Chinese Embroidery

Chinese Embroidery